We conduct Pre-Insurance Inspection surveys for both Motor and Non Motor classes of Insurance. Before a Policy cover is issued by the Insurers, we are intimated the type of asset and location to be fully inspected against the provided documentation. A thorough report is then prepared for the Insurers so that they may issue the relevant insurance policy cover on an immediate basis to facilitate their clientele.

A thorough Risk Assessment minimizes the risk of adverse events or damages, may it be Fire & Allied Perils, MBD, Bodily Injury, Business Interruption, etc; a correct cover issued and coverage is assigned.

Each hazard should be studied to determine its’ level of risk. To research the hazard, we look at:

- Product information / manufacturer documentation.

- Past experience (knowledge from workers, etc.).

- Legislated requirements and/or applicable standards.

- Industry codes of practice / best practices.

- Health and safety material about the hazard, research studies, or other manufacturer information.

- Information from reputable organizations.

- Results of testing (atmospheric or air sampling of workplace, swabs, etc.).

- The expertise of an occupational health and safety professional.

- Information about previous injuries, illnesses, near misses, incident reports, etc.

- Observation of the process or task.

Whilst conducting a risk assessment, we initially:

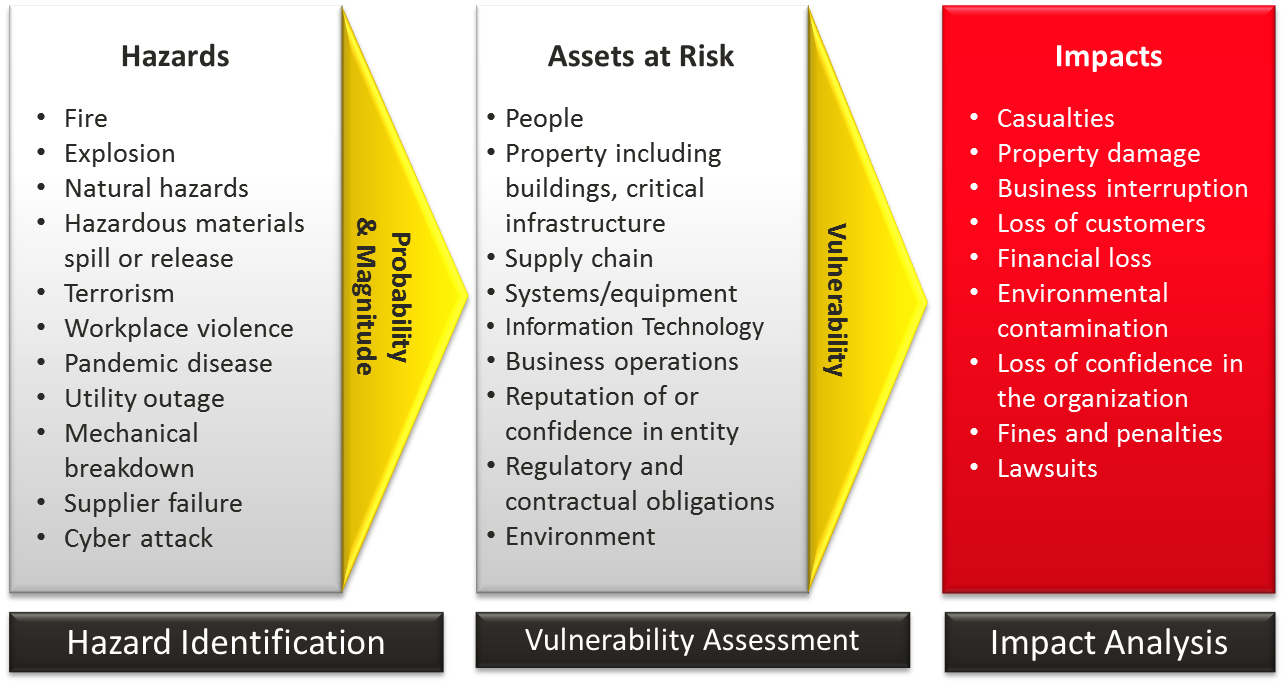

- Identify hazards and risk factors that have the potential to cause harm (hazard identification).

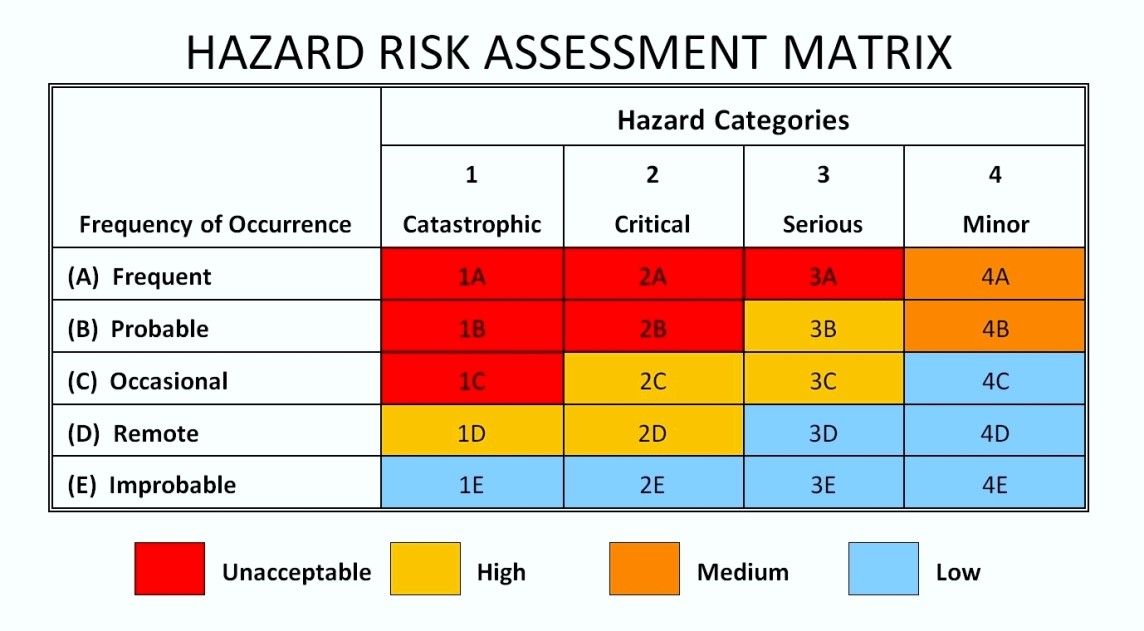

- Analyze and evaluate the risk associated with that hazard (risk analysis, and risk evaluation).

- Determine appropriate ways to eliminate the hazard, or control the risk when the hazard cannot be eliminated (risk control).

During our assessment, we examine the workplace processes and environment; to identify situations, processes, etc. that may cause harm, to the workplace and people. After identification is made, we analyze and evaluate how likely and severe the risk is. When this determination is made, we decide what measures should be in place to effectively eliminate or control the harm from happening.

- Risk assessment – the overall process of hazard identification, risk analysis, and risk evaluation.

- Hazard identification – the process of finding, listing, and characterizing hazards.

- Risk analysis – a process for comprehending the nature of hazards and determining the level of risk.

Notes:

(1) Risk analysis provides a basis for risk evaluation and decisions about risk control.

(2) Information can include current and historical data, theoretical analysis, informed opinions, and the concerns of stakeholders.

(3) Risk analysis includes risk estimation.

- Risk evaluation – the process of comparing an estimated risk against given risk criteria to determine the significance of the risk.

- Risk control – actions implementing risk evaluation decisions.

Note: Risk control can involve monitoring, re-evaluation, and compliance with decisions.

Risk assessments are very important as they form an integral part of an occupational health and safety management plan. They help to:

- Create awareness of hazards and risk.

- Identify who may be at risk (e.g., employees, cleaners, visitors, contractors, the public, etc.).

- Determine whether a control program is required for a particular hazard.

- Determine if existing control measures are adequate or if more should be done.

- Prevent injuries or illnesses, especially when done at the design or planning stage.

- Prioritize hazards and control measures.

- Meet legal requirements where applicable.

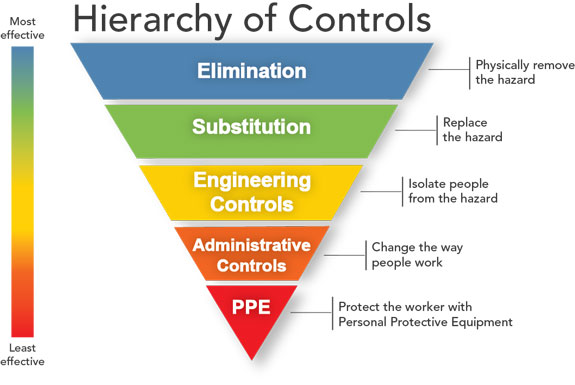

The aim of the risk assessment process is to evaluate hazards, then remove that hazard or minimize the level of its risk by adding control measures, as necessary.

There may be many reasons a risk assessment is needed, including:

- New Insurance Cover.

- Before new processes or activities are introduced.

- Before changes are introduced to existing processes or activities, including when products, machinery, tools, equipment change or new information concerning harm becomes available.

- When hazards are identified.

SOME INPORTANT DEFINITIONS

- Hazard: Anything (e.g. condition, situation, practice, behaviour) that has the potential to cause harm, including disease, death, environment or property and equipment damage.

- Hazard Identification: The process of examining each work area and work practice for the purpose of identifying all the hazards.

- Risk: The likelihood or probability that a hazardous event will occur.

- Risk Assessment: The process of assessing tasks and the risks associated with them. This is usually done by applying a risk score to each task which will ultimately show the consequences if nothing is done e.g. minor or major injury or death.

- Risk Control: Process of identifying the most cost effective methods of eliminating or controlling a hazard. Using the Hierarchy of control.

Monitoring and Review: Involves ongoing monitoring of the hazards identified and ensuring the procedures in place are being adhered to.